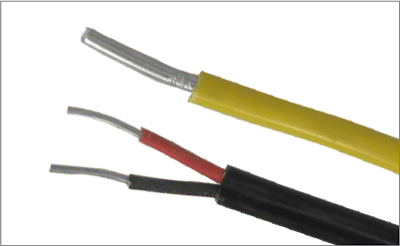

Aluminum is utilized in different types of industries so

much because it is generally low-cost and it can be suitable a mixed bag of environments.

It is also a metal that is really limitless so there is minimal chance that the

supply of aluminum will ever run out. When you require an Aluminum

cable framework, you need materials that will be ready to face the

work and not fail. Chanda Overseas Aluminum Cable Systems enable to enhance mileage because of mass savings and lighter, simpler vehicle assembly, while decreasing the sensitivity to copper commodity instability.

|

| Aluminum Cable |

Benefits:

- Reduced weight brings down equipment mass and helps to enhance vehicle mileage

- Replaces copper, which costs more than aluminum, improving the expense viability of wire gathering

- Proven end execution and consumption assurance

- Aluminum cable coordination into the standard electrical/electronic framework

- Expertise and experience in cable development and electrical/electronic framework outline

- Technical support with a frameworks point of view

- Global certify, house wiring testing and approval

- Participation on worldwide cable and wiring industry standards and activities empowers a thorough comprehension of industry needs.

The

Properties of Aluminum

Aluminum is a metal with low natural stacking. All through

the world, this metal is the second most generally utilized alongside iron. On

the other hand, it is more powerful than iron and it can possibly last considerably

more. Aluminum cable includes numerous attractive properties such as:

- It is not heavy weight

- It has best malleability

- It has great consumption resistance

- It is high quality

- It is incredible for simple machining

- It is truly easy to factory, cut, twist, bond, drill, punch, tape and weld.

When

aluminum is no more required, it can easily be reused so it can be utilized for

all intents and purposes forever. This is the main reason behind why the supply

of aluminum is thought to be generally unending. Aluminum can be reused and

reused again and again without the danger of it perpetually losing any of its attractive

properties. For instance, regardless of the fact that a bit of aluminum is

reused several times, it still remains powerful, low weight and it keeps up maximum

corrosion resistance.

On

the off chance that you are attempting to make your business more eco-friendly,

aluminum is an incredible material to utilize. When you are done utilizing it,

you can easily have it reused and you never need to stress over it investing

decades in a landfill some place. Chanda Overseas Aluminum

Cable Systems incorporate a lightweight wiring and cost-effective option that

presents to 47% mass reduction contrasted with conventional copper core cable. Approximately

1 kg of aluminum can supplant 2 kg of copper, giving equivalent conductivity.

Aluminum cable

is bigger than copper cable because of the more noteworthy cross area of aluminum

required, yet it accomplishes the same conductivity.